Developed in partnership with the Materials Department of ETH University in Zurich, the Rhopoint ID provides a new and innovative way to measure transparent appearance of materials which is highly correlated to customer perception. It quantifies the see‐through qualities of materials in a method that can be matched to real world conditions and offers the ability to measures small sample sizes and curved surfaces that simply cannot be measured with a traditional haze meter.

The patented measurement technique represents a breakthrough in transmission measurement developed in one of the words most prestigious materials analysis departments.

A backlit, high accuracy, reference target graticule functions as the viewed object, creating a highly defined pattern of light intensities with optimally sharp transitions between the backlit and masked areas.

The camera works like the human eye quantifying changes in the transmission of the light caused by a test material.

Image analysis techniques are used to characterise these effects into parameters which correlate closely with human perceptions.

What does the Rhopoint ID measure?

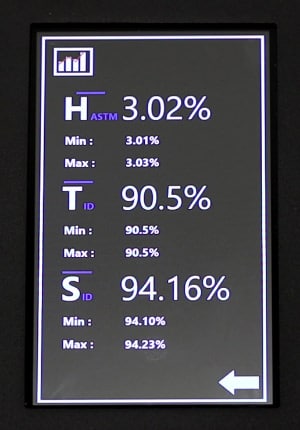

With a single button press, the instrument measures:

Haze: Quantifies the loss of contrast for objects viewed through a material.

This is measured directly by evaluating contrast of the black and white areas on the graticule. Measurements made with the Rhopoint ID are fully comparable with those made on an ASTM D1003 haze meter.

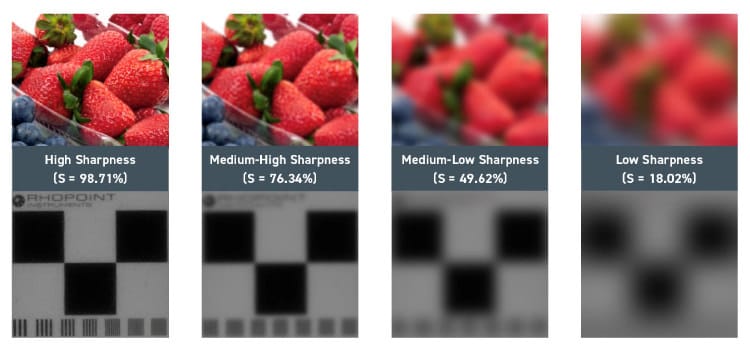

Sharpness: Sharpness quantifies the loss of perceived detail for objects viewed through a material.

When viewed through a material with high sharpness, an object appears sharp and distinct. As material sharpness decreases, the object appears blurry and obscured.

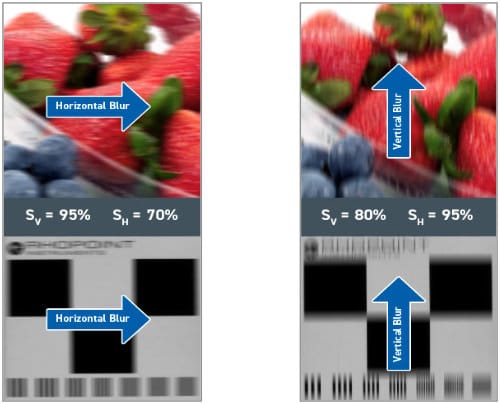

The Rhopoint ID is the only instrument that can measure directional effects in materials.

The images above show the visual impact of different ID Sharpness (S) values in vertical and horizontal directions*

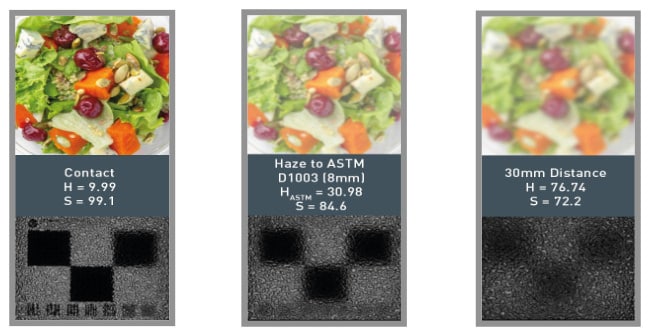

Distance Dependency (Haze & Sharpness)

Many materials exhibit a variation of transparency depending on whether the material is in contact with a viewed object or separated by an ‘air gap’ distance between them. This important metric can ONLY be measured with the Rhopoint ID.

What benefits does the Rhopoint ID offer over a traditional ASTM D1003 Haze meter?

- The ability to measure small samples that cannot be measured with a traditional haze‐ meter. The Rhopoint ID can measure samples down to 6mm x 2mm* which makes it ideally suited to applications such as blister packaging.

- The Rhopoint ID is also able to measure curved surfaces which makes it the first instrument of its kind that can be used by the PET bottle industry.

- Its fully sealed design provides a safe and accurate way of measuring liquids without the fear of damaging the instrument.

- The Rhopoint ID can be configured to replicate the final use application of a material, from “material in contact” to a 40mm gap between the test sample and a viewed object. This method allows optical performance to be assessed using real world conditions.

- Utilising the ‘live view’ camera function of the software, areas of interest can easily be identified and the sample positioned for measurement very quickly.

- Multiple instruments can be installed and connected to a LAN, ID software is free to install on multiple computers so any computer can run and interrogate results from any instrument.

Who can use this technology?

This new technology can be used by any current user of ASTM D1003 haze meters or for any application where the measurement of transparent appearance is important such as:

- PET Bottles

- Blown film

- Food film

- Medical films

- Glass

- Abraded materials

- Privacy glass / films

*Requires Rhopoint ID‐L version which includes analysis software.

Full product information:

https://www.rhopointinstruments.com/product/rhopoint_id_imaging_transmission_meter/