Measure the transmission haze and imaging transmission of food packaging.

The Rhopoint ID measures non-contact appearance – A measurement of the appearance of an object viewed through a material with an air gap between the two.

Quality control test instruments for the flexible packaging industry sector. Our Instruments are designed to improve packaging line speeds and reduce costs by producing materials that have the same batch to batch quality.

The Hanatek brand has established a reputation for supplying test instruments that control operator variable factors ignored by other producers whilst still providing a simple user interface.

Measure the transmission haze and imaging transmission of food packaging.

The Rhopoint ID measures non-contact appearance – A measurement of the appearance of an object viewed through a material with an air gap between the two.

Test instruments for measuring the visual properties of printed materials such as rub and abrasion testing and gloss measurement.

Measurement of friction properties of printed film or paper.

Quality control test instruments for improving packaging speeds.

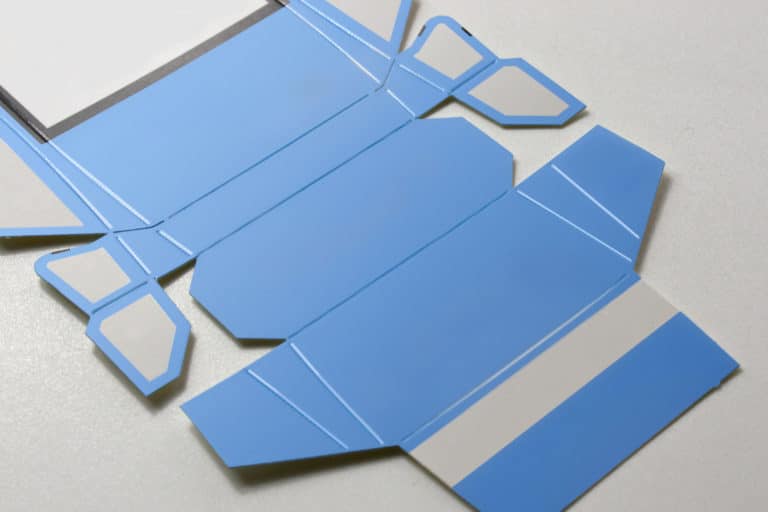

Measure carton crease and board stiffness, whole carton opening force and experiment to find the correct crease profile with the carton crease proofer.

Sample preparation of individual creases and whole cartons for testing.

Test instruments for the repeatable measurement of thickness, friction and shrink properties of plastic film.

Accurate control of these parameters can lead to a reduction in raw material costs.

Visual control of haze and rub resistance of materials.

Hanatek instruments are designed to be used in both research & development and production environments in numerous industries.

Measure how a folded carton will perform on a high speed packaging machine.

Measure crease recovery (spring back force), board stiffness.

Instant display of crease to board stiffness ratio.

Static and dynamic friction measurement of flexible packaging materials.

Measure the COF of paper, film and foils to ASTM D1894 and ISO 8295. Automatic sled placement with variable dwell times give more repeatable static slip results

Measure the durability of inks and coatings on any printed material.

The instrument is used for testing the scuff, marking and rub resistance of cartons, films and commercial printed material.

This comparative test works by abrading a printed sample against a reference material under known conditions.

The results can be used to identify alternative substrates, better ink and coating formulations or the suitability of finished cartons or films

Hanatek Thickness Gauges are designed to quickly and accurately measure the thickness of a variety of substrates including film, paper, board, foil, tissue and textiles.

Operated via an intuitive touch screen interface the instrument will allow the user to define batch size, dwell time & measuring speed to meet the requirements of many international standards.

Hanatek instruments are designed to be used in both research & development and production environments in numerous industries.

Measure how a folded carton will perform on a high speed packaging machine.

Measure crease recovery (spring back force), board stiffness.

Instant display of crease to board stiffness ratio.

Static and dynamic friction measurement of flexible packaging materials.

Measure the COF of paper, film and foils to ASTM D1894 and ISO 8295. Automatic sled placement with variable dwell times give more repeatable static slip results

Measure the durability of inks and coatings on any printed material.

The instrument is used for testing the scuff, marking and rub resistance of cartons, films and commercial printed material.

This comparative test works by abrading a printed sample against a reference material under known conditions.

The results can be used to identify alternative substrates, better ink and coating formulations or the suitability of finished cartons or films

Hanatek Thickness Gauges are designed to quickly and accurately measure the thickness of a variety of substrates including film, paper, board, foil, tissue and textiles.

Operated via an intuitive touch screen interface the instrument will allow the user to define batch size, dwell time & measuring speed to meet the requirements of many international standards.